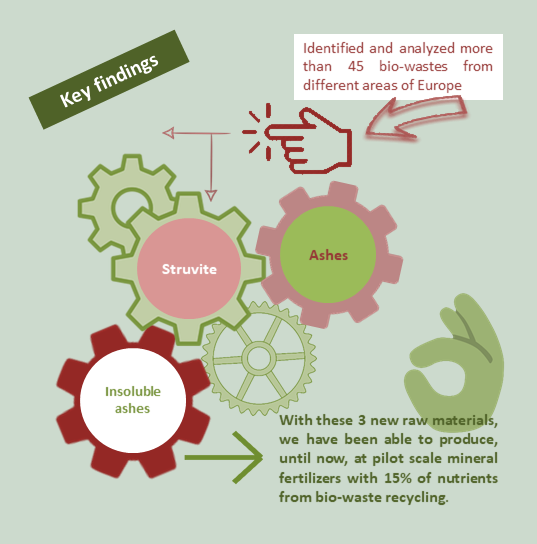

The first step was an intensively search of the European industry landscape -municipal and agricultural waste management- to identify promising sources of biobased residues. The result was a total of 23 different samples of residues that have been chemically and physically analyzed and characterized. Acceptability criteria for possible biobased residues have been defined, in order to identify possible new feedstocks for the fertilizer production. A full list of beneficiation and pre-treatment steps has been filed.

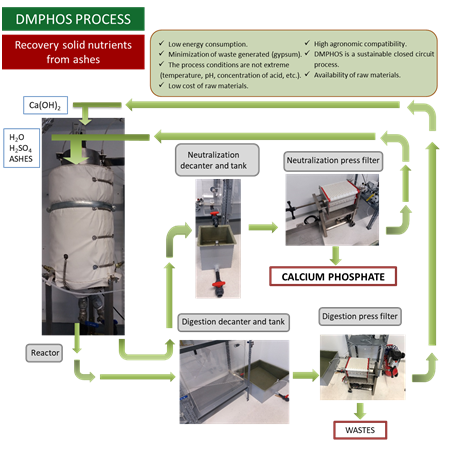

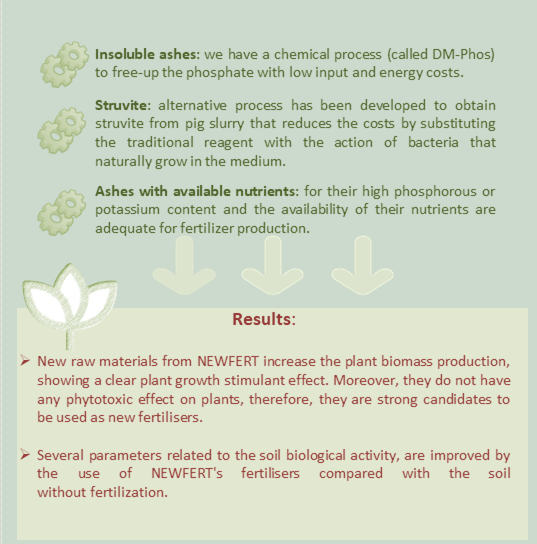

Great part of the work was dedicated to the study of nutrient recovery from solid waste providing materials potentially suitable for application and feed material for fertilizer production. It identifies and categorizes available technologies and shows potential implementation in fertilizer production and upgrade. Its main purpose is to identify feasible bio-solid waste (like waste incineration ashes) in order to extract phosphorous/nitrogen/potassium eligible for NPK fertilizer use, select the optimum chemical extraction process and design the industrial process for chemical nutrients extraction process suitable to be used in the already existing NPK fertilizer plant. An important outcome of the project was the design of a new chemical nutrients extraction process, including the design and construction of a test bench to set up the designed process. With the results obtained, it was possible to design the industrial process for chemical nutrients extraction process suitable to be use in existing NPK fertilizer plant.

Regarding to liquid wastes a semi-industrial scale pilot has been implemented in an anaerobic digestion unit at a pig farm in Morbihan (France) with the objective of recover struvite. Trials to optimize the crystallization were performed initially in the lab scale pilot and then the process was scaled-up to pilot plant. The bio-based raw materials obtained were granulated to obtain the NEWFERT’s NPK fertilizers.

inally, a new family of biobased NPK fertilizers have been designed, and the agronomic trials indicated that the substitution of the raw materials produced, overall, a fertilizer efficiency similar to that of the conventional NPK fertilizers with the same equilibrium. A more in detail analysis on the agronomic effect of the substitution of conventional raw materials, reveals the following findings: The NEWFERT’s NPK fertilizers NF-01 (PK fertiliser), NF-12 (Struvite mix) and NF-25 (biowaste ashes), has similar effect than the corresponding conventional fertilizer in barley plants in the acid soil, and the treatments NF-12 (Struvite mix) and NF-04 (Cyclone ash) in the basic soil. The NPK fertilizer NF-12 (Struvite mix) improved the effect of the conventional fertiliser. However, the best NPK fertilizer in barley and in acid soil was the NF-25 (biowaste ashes), whereas NF-12 (Struvite mix) showed a clear fertiliser effect in barley plants and in both soils, the acid and the basic ones. On the other hand, the performance of the NEWFERT’s NPK fertilizer NF-04 (Cyclone ash) was better than that of the C+ (conventional fertiliser) in both crops: barley and maize in basic soil. In addition to the NPK fertilizer NF-04, NF-41 and NF-42 (Phosphate) also produced a similar growth compared to C+ in the maize assay.

Regarding environmental effects of the NEWFERT’s NPK fertilizers, the most relevant aspect is that none of the indexes used to estimate the soil biological activity showed a significant alteration because of the substitution of the raw materials in the fertiliser granule by the new bio-based materials, which means a lack of modification of the mentioned indexes between the treatments and the positive control.

In relation to the exploitation results NEWFERT has developed a new innovative technology to recover nutrients from bio-waste in the fertiliser industry. These new technologies will permit the partial substitution of traditional raw materials in the fertilizer production, by recycled organic materials. One of the technologies for nutrients recovery, has been patented by D&M and Fertiberia (EP17382535.7: PROCESS AND INSTALLATION FOR THE RECOVERY OF PHOSPHORUS FROM WASTE INCINERATION ASH, date of embargo: 02/02/2019). Proman will increase its experience in consultancy about waste as source of raw materials to design fertilisers, and will contribute to the dissemination of the results at the end of the project. IRSTEA has developed a new and more efficient technology for phosphate recovery through the production of struvite. This technology will be offered to waste and water treatment companies. University of Leon will develop a new more efficient technology for nitrogen reduction through the bioelectrochemical systems and KWB will increase its knowledge about the fertiliser process and will increase its possibilities of offering consultancy in this subject.

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency. Neither the European Union nor the granting authority can be held responsible for them